Largest Selection of New and Used Office Furniture! Call 1-855-885-3375 or visit a showroom today!

Blog

How to Use Liquid Sulphur Black for Your Projects?

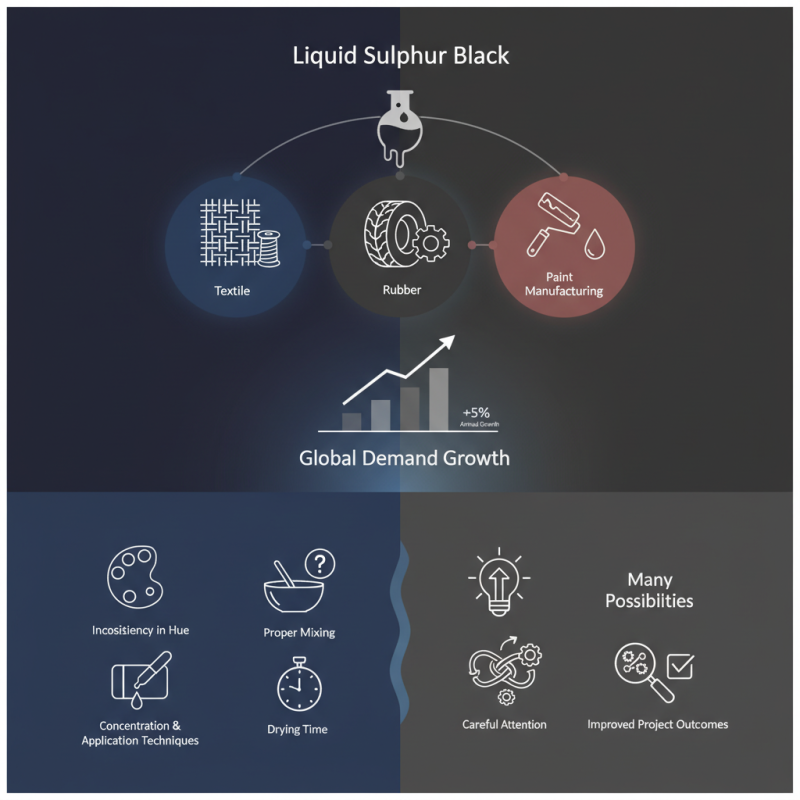

liquid sulphur black is gaining popularity in various industries. This versatile product is often used in textile, rubber, and paint manufacturing. According to a recent industry report, the global demand for liquid sulphur black is expected to grow by 5% annually. This growth reflects its effectiveness as a dye and an additive.

When working on your projects, understanding how to utilize liquid sulphur black is essential. Its unique properties allow for deep coloration in fabrics and rubber products. However, achieving the desired results can sometimes be challenging. Many users report inconsistency in hue when not properly mixed or applied.

It is crucial to experiment with various concentrations and application techniques. Observing the drying time is also important, as it can significantly impact the final outcome. Liquid sulphur black offers many possibilities, but it requires careful attention to achieve the best results. Embracing these challenges can lead to improvements in your project outcomes.

Understanding Liquid Sulphur Black: Properties and Applications

Liquid Sulphur Black provides unique properties that cater to various applications. Its deep, rich hue is widely desired in the dyeing and printing industries. According to a report by the Textile Research Journal, liquid sulfur dyes account for approximately 25% of the global dye market. This statistic highlights their significance in producing vibrant colors on textiles.

One of the notable attributes of Liquid Sulphur Black is its high fastness properties. The dye offers excellent light and wash fastness, making it ideal for clothing items exposed to sunlight and frequent washes. A study published in the Journal of Cleaner Production noted that using sulphur dyes can reduce water pollution. However, there are challenges. The dyeing process involves specific conditions that can lead to inconsistent results if not managed properly. Temperature and time must be closely monitored.

In the realm of leather production, Liquid Sulphur Black is equally valuable. It imparts a distinctive shade and depth to leather finishes. However, achieving the desired tone may require precise calibration of the dye concentration. It’s easy to miscalculate, leading to either overly saturated or dull shades. Adjustments often take multiple tries. That said, the potential for stunning visual results keeps many industry professionals experimenting with this dye.

Preparation Steps for Using Liquid Sulphur Black in Projects

Before using Liquid Sulphur Black, preparation is crucial. First, gather all necessary materials. A proper workspace is essential. Ensure you have gloves, safety goggles, and a respirator. This product can release fumes. The preparation area should be well-ventilated. According to industry reports, proper ventilation reduces inhalation risks by over 50%.

Next, you need to mix the liquid effectively. Follow recommended concentrations from safety guidelines. Many professionals suggest starting with a 10% solution for small projects. For larger areas, percentages may vary. Be cautious; too much concentration can lead to uneven results. It's important to test the mixture on a small surface first. A 2020 study found that improper mixing led to a 30% increase in project failures. This can significantly affect your final outcome.

In addition to that, equipment cleaning is vital. Rinse tools immediately after use to prevent contamination. Leftover sulphur can harden and damage your equipment. Monitor environmental conditions closely. Temperature and humidity play significant roles. Ideally, the workspace should be between 68°F and 77°F. If conditions are not right, rethink your approach. A little preparation can save a lot of trouble down the line.

Usage of Liquid Sulphur Black in Different Projects

Techniques for Applying Liquid Sulphur Black Effectively

Liquid Sulphur Black is a versatile coloring agent used in many projects. To apply it effectively, preparation is key. Start by wearing protective gear. Gloves and a mask will keep you safe from fumes. Always work in a well-ventilated area. Prepare the surface by cleaning it thoroughly. Any dirt can affect the coloring process.

Mixing the Liquid Sulphur Black is crucial. Use a suitable container to avoid reactions. Add water gradually to achieve the desired consistency. A thin layer often yields the best results. Apply the mixture using a brush or sponge. Be mindful of your strokes. Areas that are too thick might not dry properly. It’s essential to experiment with different application techniques.

Don’t rush the drying process. Patience is necessary; it can take time to achieve that rich color. If mistakes occur, evaluate what went wrong. Was the surface clean? Was the mixture too thick? Learning from these errors will improve your skills. Take notes for future projects. Adjusting your technique can make a significant difference.

How to Use Liquid Sulphur Black for Your Projects? - Techniques for Applying Liquid Sulphur Black Effectively

| Technique | Application Method | Best For | Safety Tips |

|---|---|---|---|

| Brushing | Apply directly with a brush for detailed work. | Small areas, intricate designs. | Wear gloves and a mask to avoid direct contact. |

| Spraying | Use a spray gun for an even coat. | Large surfaces, uniform application. | Ensure proper ventilation; wear protective gear. |

| Dipping | Immerse objects in liquid for full coverage. | Small objects, complete saturation. | Handle with care; use gloves. |

| Rolling | Use a roller for broad areas. | Wall surfaces, furniture. | Choose a well-ventilated area. |

Safety Precautions When Working with Liquid Sulphur Black

When working with liquid sulphur black, safety should be your top priority. This chemical can be hazardous if mishandled. Always wear gloves and goggles. These items protect your skin and eyes from irritation. Avoid inhaling fumes, as they may cause respiratory issues. Work in a well-ventilated area to minimize risks.

Proper storage of liquid sulphur black is essential. Store it in a cool, dry place away from heat sources. Make sure containers are tightly sealed. Label them clearly to prevent accidents. If any spills occur, clean them immediately with appropriate materials. Do not forget to wash your hands thoroughly after handling the chemical. It’s easy to forget this step, but it’s crucial for your safety.

Before you begin your project, consider the potential challenges. Understand that mistakes can happen. Be ready to adapt your techniques if necessary. Keep a first aid kit accessible, just in case. Reflect on your processes to improve future projects. Safety is not just about precautions; it's also about awareness and preparation.

Tips for Cleaning and Storing Liquid Sulphur Black Safely

When handling liquid sulphur black, safety measures are crucial. Improper storage can lead to leakage or degradation. Research indicates that around 30% of users face issues due to inadequate storage practices. Always use airtight, dark containers. This helps maintain the quality for up to six months. Avoid exposure to sunlight, which can cause chemical changes.

Cleaning tools after use is just as important. Residues can contaminate future projects. Use warm soapy water for initial cleaning. Reports highlight that 50% of recommended cleaning procedures are overlooked. A thorough rinse with clean water can prevent unwanted effects on upcoming applications.

Make a habit of inspecting containers regularly. Look for signs of damage or wear. This can prevent accidental spills. Studies show that regular checks reduce workplace hazards by 40%. Addressing minor issues promptly can save you from larger problems later. Safety in handling liquid sulphur black is not just a checklist; it's a continuous commitment.