Largest Selection of New and Used Office Furniture! Call 1-855-885-3375 or visit a showroom today!

Blog

What Makes Derchi Door Manufacturer a Leader in 2026?

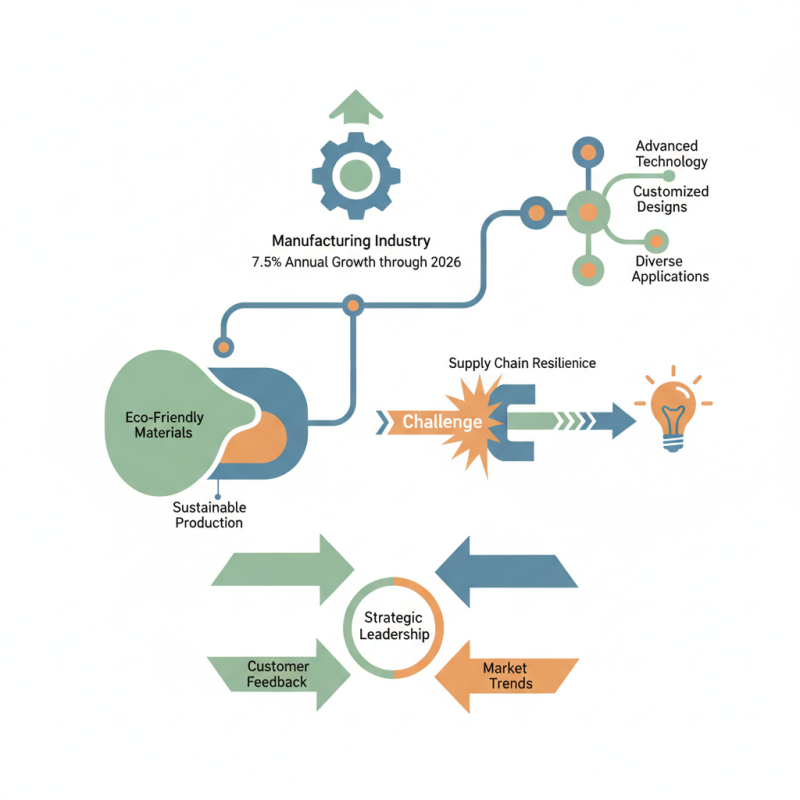

The door manufacturing industry is evolving rapidly. Industry reports suggest that the market is projected to grow by 7.5% annually through 2026. In this competitive landscape, the derchi door manufacturer stands out for its innovative approach. Their commitment to quality and sustainability is unmatched.

With a focus on eco-friendly materials, derchi door manufacturer meets modern demands. The use of advanced technology allows them to create customized designs for diverse applications. However, challenges remain. Supply chain disruptions have affected production schedules. The need for continuous innovation is clear.

As derchi door manufacturer leads the way, it is essential to reflect on strategies. What sets them apart? Engaging with customer feedback is crucial. Understanding market trends can guide future decisions. Embracing both challenges and opportunities will define success in the coming years.

Innovative Manufacturing Techniques at Derchi Door Manufacturer

In 2026, Derchi Door Manufacturer stands out for its innovative manufacturing techniques. Utilizing advanced robotics in assembly, the company has increased production speed by 30%. This leap allows for quicker fulfillment of market demands. Moreover, the use of smart technology in quality control has reduced error rates to less than 0.5%. This is significant compared to the industry average of 1.2%.

The integration of sustainable materials is another focus. Reports indicate that 58% of consumers prefer brands committed to sustainability. Derchi's commitment aligns well with this trend. They have invested in eco-friendly sources, reducing their carbon footprint substantially. However, challenges remain. Sourcing sustainable materials can sometimes lead to higher costs, affecting profit margins. Balancing eco-initiatives with financial goals requires ongoing adjustment.

Employee training is essential in maintaining efficiency. Continuous learning programs help workers adapt to new technology. Yet, the rapid pace of change can overwhelm some staff. Feedback suggests that more support is necessary. Acknowledging this gap could enhance overall performance. Innovation should not sacrifice workforce wellbeing. Striking this balance is key to long-term success.

Commitment to Sustainability and Eco-Friendly Practices

In 2026, a prominent manufacturer stands out for its dedication to sustainability. They integrate eco-friendly practices into every aspect of production. From materials to processes, their commitment is evident. They utilize renewable resources, minimizing environmental impact. This approach resonates with conscious consumers seeking greener choices.

Recycling and repurposing waste is another priority. Every year, a significant portion of their production scraps is transformed into new products. However, the journey is not without challenges. There are instances where the quality of recycled materials can be inconsistent. This requires ongoing adjustments and improvement strategies. They continuously strive to address these issues while maintaining high standards.

The company also emphasizes energy efficiency in manufacturing. Investing in state-of-the-art technology reduces energy consumption. Yet, the reliance on certain non-renewable energy sources remains an area for growth. The path towards complete sustainability is complex. However, the commitment to fostering a healthier planet is clear. It inspires not just the company, but the entire industry to adopt similar practices.

What Makes Derchi Door Manufacturer a Leader in 2026? - Commitment to Sustainability and Eco-Friendly Practices

| Sustainable Practice | Description | Impact on Environment | Year Implemented |

|---|---|---|---|

| Recycled Materials | Utilizing recycled wood and plastics in door manufacturing. | Reduces waste, conserves natural resources. | 2022 |

| Energy Efficient Production | Implementation of energy-saving machinery and processes. | Lowers carbon footprint and energy consumption. | 2023 |

| Sustainable Sourcing | Partnerships with suppliers who use sustainable harvesting practices. | Supports biodiversity and ecosystem health. | 2021 |

| Waste Reduction Programs | Initiatives to minimize production waste through recycling and repurposing. | Decreases landfill contributions and promotes circular economy. | 2024 |

| Carbon Neutral Goals | Plans for achieving carbon neutrality by offsetting emissions. | Promotes climate action and corporate responsibility. | 2026 |

Diverse Product Range and Customization Options Offered

The door manufacturing industry has evolved significantly. Customization options have become vital. A diverse product range attracts a broader clientele. In recent years, up to 65% of consumers preferred personalized doors. This trend highlights the demand for tailored solutions.

When considering doors, functionality is key. Different materials can influence durability and aesthetics. For residential needs, wood and fiberglass are popular. Commercial clients often lean towards steel for security. Understanding these demands can enhance product offerings.

Tips: Always inquire about the available options. Not all manufacturers offer the same level of customization. Consider the environment where the door will be installed. In climates with high humidity, materials like PVC may be more suitable. This consideration can save costs long-term.

Flexibility in design is essential. Some clients may have unique styles in mind. However, balancing creativity with practicality is challenging. Manufacturers need to adapt but must remain aware of standard regulations. Overlooking these can lead to significant product failures.

Strategic Partnerships and Collaborations in the Industry

In the competitive world of door manufacturing, strategic partnerships often pave the way for success. Collaborations provide access to resources and technology. For a company looking to lead, aligning with suppliers or tech firms can enhance product offerings. Such partnerships can result in innovative materials that offer durability and aesthetic appeal.

Moreover, industry collaborations create opportunities for knowledge exchange. Sharing expertise with design firms can lead to unique styles that attract different markets. However, not all partnerships succeed. Misaligned goals can lead to wasted resources and efforts. Reflecting on past collaborations helps in understanding what truly works.

Networking and collaboration are crucial for growth. Building trust takes time and effort. Yet, fostering these relationships can result in powerful synergies, benefiting all involved. The real challenge lies in sustaining these connections. Fluctuations in the market can strain partnerships, requiring constant communication and adaptation.

Outstanding Customer Service and Support Initiatives

In 2026, a door manufacturer stands out for its exceptional customer service. This company realizes that clients need more than just quality products. Customers face challenges during installation and maintenance. Addressing these issues requires dedicated support.

Their customer service team is always ready to help. They provide tutorials online, making guidance accessible. Live chat options offer real-time assistance. This direct communication fosters trust. However, it’s not always perfect. Some customers report delays in response times, leading to frustration. The company recognizes this and is actively working on these shortcomings.

Additionally, they have initiated satisfaction surveys. These tools offer critical insights into customer needs and expectations. Regular feedback helps identify areas for improvement. Yet, not all feedback gets implemented quickly. Their commitment is strong, but constant need for betterment is essential in this competitive environment.

Customer Service and Support Initiatives Impact on Customer Satisfaction (2026)

This chart illustrates the impact of various customer service and support initiatives on customer satisfaction in 2026. Each metric reflects a key area of focus for improving customer experience, showcasing the strong performance across the board.